Product Description:

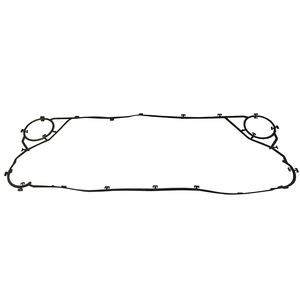

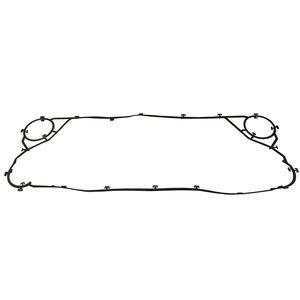

A gasketed plate heat exchanger is an essential component in various industries, providing efficient heat transfer capabilities. One crucial element of a gasketed plate heat exchanger is the Plate Heat Exchanger Gaskets, which play a vital role in ensuring optimal performance and preventing leaks.

The Plate Heat Exchanger Gaskets are available in different profiles to suit various applications. These profiles include Flat, Raised, and Grooved gaskets, each offering unique benefits depending on the specific requirements of the system.

For the Plate Heat Exchanger Gaskets with a dimension of Centre To Centre: 394mm*126mm, they are designed to fit a specific plate heat exchanger model, ensuring a precise and secure fit for reliable operation.

These gaskets are commonly used in HVAC systems and the textile industry, where heat exchange is a critical process. The gaskets' ability to maintain a tight seal even under high pressure conditions makes them suitable for applications where the pressure range can go up to 10 bar.

One of the key features of the Plate Heat Exchanger Gaskets is the Start Gasket, which is cut from 2pcs Channel Gaskets. This design ensures a consistent and reliable seal along the plate heat exchanger, minimizing the risk of leaks and optimizing heat transfer efficiency.

Applications:

The Plate Heat Exchanger Gaskets are essential components designed for use in Gasket Plate Heat Exchangers. With a size that can be either standard or customized, these gaskets are specifically crafted to fit the dimensions of the heat exchanger, with a centre-to-centre measurement of 394mm by 126mm.

The gaskets are made from high-quality stainless steel material, ensuring durability and resistance to corrosion, making them ideal for various industrial applications. Their flat gasket shape allows for a secure seal between the plates of the heat exchanger, preventing leakage and ensuring efficient heat transfer.

Operating at a maximum pressure of 3.0 MPaG, these Plate Heat Exchanger Gaskets are suitable for a wide range of applications across different industries. They are commonly used in Heat Exchanger Gasket Replacement tasks, where existing gaskets have worn out or become damaged, causing leaks and inefficiencies in the heat exchange process.

Whether it is in HVAC systems, chemical processing plants, food and beverage production facilities, or any other industry requiring heat transfer solutions, these gaskets play a crucial role in maintaining the performance of Gasketed Plate Heat Exchangers. Their reliable sealing properties help optimize heat transfer efficiency and minimize energy consumption.

Engineered to meet stringent quality standards, these gaskets ensure a tight and secure fit within the heat exchanger, allowing for smooth operation even under high pressures. Their versatility in terms of sizing and materials make them a versatile solution for various heat exchange applications.

In conclusion, the Plate Heat Exchanger Gaskets are indispensable components for Gasketed Plate Heat Exchangers, offering a reliable and efficient solution for heat transfer needs in a wide range of industrial settings.

Customization:

Product Customization Services for Heat Exchanger Gaskets:

Size: Standard Or Customized

Liquid Flow Rate: 2.5m/s

Surface Area: 1.45㎡

Standard: Globle Standard

Operating Pressure: 3.0 MPaG Max.

Support and Services:

Our Product Technical Support and Services for Plate Heat Exchanger Gaskets include:

- Expert guidance on selecting the right gasket material for your specific application.

- Assistance with installation and maintenance procedures to ensure optimal performance.

- Troubleshooting support to address any issues or concerns you may have with the gaskets.

- Access to documentation and resources for product specifications and technical information.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!