Product Description:

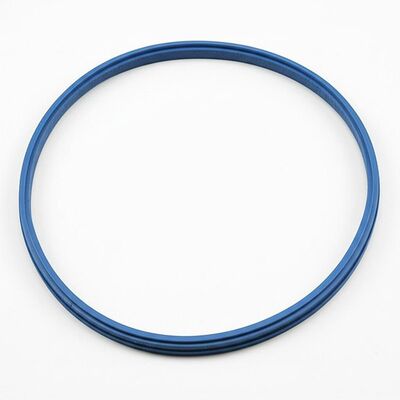

The Heat Exchanger Gasket is an essential component designed specifically for plate type heat exchangers, ensuring optimal performance and reliability in various industrial applications. Manufactured to meet rigorous standards, this gasket is engineered to provide a secure seal between the plates of a gasketed plate heat exchanger, preventing leaks and maintaining efficient heat transfer.

With a standard weight specification, this PHE Gasket is crafted to offer durability and resilience under a wide range of operating conditions. The design accommodates a plate type style heat exchanger, making it an ideal replacement or upgrade for existing systems that require a reliable sealing solution. The gasket’s dimensions are precisely tailored to fit a centre to centre size of 1868mm by 600mm, ensuring compatibility and ease of installation without compromising the integrity of the heat exchanger.

One of the standout features of this gasket is its ability to withstand temperatures ranging from -5℃ to 150℃. This wide temperature range makes it suitable for numerous applications, including those involving hot liquids, steam, or chilled fluids. The material composition of the gasketed plate heat exchanger rubber is selected to maintain flexibility and sealing effectiveness despite temperature fluctuations, minimizing the risk of leaks and extending the life of the heat exchanger.

Durability is further enhanced by the quality of the rubber used in the PHE Gasket. This rubber is designed to resist chemical corrosion, wear, and aging, which are common challenges in heat exchanger environments. As a result, users can expect consistent performance over time, reducing maintenance intervals and associated downtime. The gasket’s resilience also contributes to energy efficiency by ensuring that heat transfer processes operate without interruption or loss due to sealing failures.

The product is backed by a 12-month manufacturer warranty, reflecting the confidence in its quality and reliability. This warranty offers peace of mind to users, guaranteeing that any manufacturing defects or premature failures will be addressed promptly. It underscores the manufacturer’s commitment to delivering a high-quality PHE Gasket that meets industry standards and customer expectations.

Installation of this gasket is straightforward due to its exact sizing and compatibility with standard plate type heat exchangers. Maintenance and replacement are simplified, enabling quick turnaround times during scheduled servicing or unexpected repairs. This ease of use helps to maintain continuous operation of heat exchanger systems, which is critical in industries such as HVAC, chemical processing, food and beverage, and power generation.

In summary, the Heat Exchanger Gasket offers a robust and reliable sealing solution for plate type heat exchangers. Its standard weight, precise size of 1868mm by 600mm centre to centre, and ability to operate within a temperature range of -5℃ to 150℃ make it a versatile choice for many industrial applications. The use of high-quality gasketed plate heat exchanger rubber ensures long-lasting performance, while the 12-month manufacturer warranty provides additional assurance of quality and dependability. Whether you are replacing an old gasket or upgrading your system, this PHE Gasket is designed to deliver superior sealing performance, efficiency, and durability.

Applications:

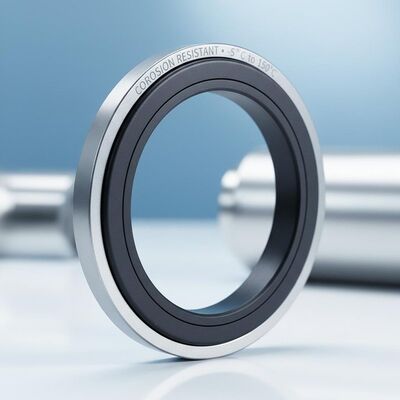

The S14 model Plate Heat Exchanger Gasket is an essential component designed to ensure optimal sealing performance in various heat exchanger systems. Manufactured in China, this PHE Gasket boasts a high level of corrosion resistance, making it ideal for use in demanding industrial environments where exposure to aggressive fluids and chemicals is common. With its rectangular sectional shape, the gasket fits precisely into plate heat exchangers, providing a reliable seal that prevents leaks and maintains system efficiency.

One of the standout features of the S14 Plate Heat Exchanger Gasket is its ability to withstand high temperatures, thanks to its HNBR material composition. This gasket can endure heat resistance up to 140°C, making it perfect for applications involving hot fluids and steam. This thermal durability ensures that the gasket maintains its integrity and sealing performance even under prolonged exposure to elevated temperatures, reducing the risk of system failures and downtime.

The S14 model is widely used across various industries, including chemical processing, food and beverage production, HVAC systems, and power generation. In chemical plants, the corrosion-resistant properties of this Plate Heat Exchanger Gasket allow it to handle aggressive media without degrading. In food processing, its heat resistance and secure sealing help maintain hygiene standards by preventing contamination between different fluid streams.

Additionally, the PHE Gasket is commonly applied in HVAC systems to facilitate efficient heat transfer while minimizing energy loss. In power plants, the gasket’s durability and resistance to harsh operating conditions contribute to the reliable performance of heat exchangers, which are critical for maintaining optimal thermal management.

With a 12-month manufacturer warranty, the S14 Plate Heat Exchanger Gasket offers customers peace of mind regarding product quality and longevity. Its robust construction and material selection ensure that it remains a dependable choice for maintaining the performance and safety of plate heat exchanger units across a range of application occasions and scenarios.

Customization:

Our PLATE HEAT EXCHANGER GASKET, model number S14, is expertly designed to meet the demanding requirements of heat exchanger systems. This Gasketed Plate heat exchanger rubber is manufactured in China, ensuring high-quality standards and reliable performance. With a sectional shape of rectangle, it fits perfectly in various plate heat exchanger configurations.

Engineered to withstand temperatures ranging from -5℃ to 150℃, the S14 gasket features HNBR material that is heat resistant up to 140℃, providing excellent durability and sealing under high thermal conditions. The product comes with a standard weight specification to maintain optimal efficiency and ease of installation.

Our PHE Gasket customization service allows you to tailor the gasket to your specific operational needs, ensuring compatibility and enhanced performance in your heat exchanger system. Trust our expertise to deliver a reliable sealing solution that prolongs equipment life and minimizes maintenance requirements.

Support and Services:

Our Heat Exchanger Gaskets are designed to provide reliable sealing performance under various operating conditions. To ensure optimal functionality and longevity of the product, please follow the installation guidelines and maintenance instructions provided in the product manual.

If you encounter any issues with the gasket, such as leakage or material degradation, inspect the gasket for proper alignment, surface cleanliness, and compatibility with the fluids involved. Replacement gaskets should match the original specifications to maintain system integrity.

For technical support, our team of experts is available to assist with troubleshooting, installation advice, and product selection to meet your specific heat exchanger requirements. We also offer on-site inspection and maintenance services to help extend the lifespan of your equipment.

Regular maintenance and periodic inspection of the heat exchanger gaskets are recommended to prevent unexpected downtime and ensure efficient system operation. Please refer to the maintenance schedule outlined in the product documentation for detailed instructions.

We are committed to providing high-quality products and services to support your operations. For further technical assistance or service inquiries, please consult our support resources or visit our website for additional information.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!