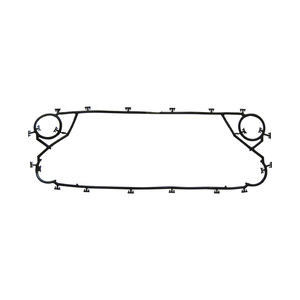

Product Description:

The Heat Exchanger Gasket is an essential component designed to ensure the optimal performance and longevity of various types of heat exchangers, including plate and shell and tube models. Manufactured with precision and high-quality materials such as graphite, rubber, PTFE, and metal, this gasket provides excellent sealing properties that prevent leaks and maintain the efficiency of heat exchange processes. Its robust design and superior material composition allow it to withstand harsh operating conditions, making it ideal for industrial applications where reliability and durability are paramount.

One of the standout features of the Heat Exchanger Gasket is its high corrosion resistance. This attribute is crucial because heat exchangers often operate in environments where exposure to corrosive fluids and extreme temperatures is common. The gasket's resistance to corrosion ensures that it maintains its integrity over extended periods, reducing the need for frequent replacements and minimizing downtime. This makes it a cost-effective solution for industries such as chemical processing, power generation, and HVAC systems.

The gasket is especially suitable for use as a Gasketed Plate heat exchanger rubber, which is widely recognized for its flexibility and sealing capabilities. The rubber material used in these gaskets offers excellent elasticity and compression recovery, ensuring a tight seal between the plates of the heat exchanger. This tight seal is vital to prevent cross-contamination of fluids and to maintain the efficiency of the heat transfer process. Additionally, the rubber gaskets are designed to withstand various chemical exposures and temperature fluctuations, further enhancing their performance in demanding environments.

In addition to rubber, the Heat Exchanger Gasket is also available in graphite, PTFE, and metal materials, each offering unique benefits tailored to specific applications. Graphite gaskets provide exceptional thermal resistance and chemical stability, making them suitable for high-temperature and corrosive environments. PTFE gaskets offer outstanding chemical resistance and are ideal for applications involving aggressive chemicals. Metal gaskets combine durability with high-pressure resistance, making them suitable for heavy-duty industrial heat exchangers.

The versatility of the Heat Exchanger Gasket extends to its compatibility with various heat exchanger types. Whether you are working with a plate heat exchanger, a shell and tube heat exchanger, or other configurations, this gasket is designed to fit seamlessly and perform reliably. Its design ensures easy installation and replacement, which helps in maintaining the operational efficiency of the heat exchanger without significant downtime.

Transporting these gaskets is also hassle-free, as they come packaged in standard export cartons that protect the product during shipping and handling. This packaging ensures that the gaskets arrive at their destination in pristine condition, ready for immediate use. The standard export carton packaging also simplifies logistics, making it easier for businesses to stock and distribute these essential components.

In summary, the Heat Exchanger Gasket is a high-performance sealing solution that combines durability, corrosion resistance, and material versatility. Whether you require a Gasketed Plate heat exchanger rubber for general sealing needs or specialized graphite, PTFE, or metal gaskets for more demanding applications, this product meets and exceeds industry standards. Its compatibility with various heat exchanger types, including plate and shell and tube models, along with its superior corrosion resistance, makes it an indispensable component in maintaining the efficiency and safety of heat exchange systems across multiple industries.

Applications:

The Heat Exchanger Gasket model S14 is designed to meet the demanding requirements of various heat exchanger applications, making it an essential component in many industrial and commercial settings. This versatile gasket is compatible with different types of heat exchangers, including plate heat exchangers (PHE) and shell and tube heat exchangers, ensuring a broad range of application possibilities. Its customizable dimensions allow it to be precisely tailored to fit specific heat exchanger models, providing a perfect seal and optimal performance.

One of the key strengths of the S14 gasket lies in its material variety. Available in NBR, EPDM, HNBR, HEPDM, Viton, FKM, and HTNBR, the gasket ensures compatibility with various fluids and operational environments. These materials offer excellent resistance to heat, chemicals, and corrosion, making the gasket particularly suitable for use in harsh conditions where durability and reliability are critical. The gasket’s heat resistance up to 170°C makes it ideal for applications involving high-temperature fluids, ensuring consistent sealing performance without degradation.

In practical terms, the S14 PHE gasket is widely used in industries such as HVAC, chemical processing, food and beverage production, pharmaceuticals, and power generation. It is especially valuable in plate heat exchanger systems where efficient thermal transfer and leak prevention are crucial. The PLATE HEAT EXCHANGER GASKET ensures that the heat exchanger operates efficiently by maintaining tight seals between the plates, preventing cross-contamination of fluids and minimizing downtime caused by leaks.

Moreover, the corrosion-resistant properties of the S14 gasket enhance the longevity of heat exchangers by protecting against chemical damage and wear over time. This makes it an excellent choice for facilities handling aggressive fluids or operating under fluctuating temperature conditions. The gasket’s performance reliability supports maintenance schedules and reduces the frequency of replacements, contributing to cost savings and operational efficiency.

Overall, the Heat Exchanger Gasket S14 is a robust, adaptable, and high-performance sealing solution suitable for a wide array of heat exchanger applications. Whether used as a PHE gasket or in shell and tube heat exchangers, it guarantees superior sealing, durability, and resistance to heat and corrosion, meeting the stringent demands of modern industrial processes.

Customization:

Our Heat Exchanger Gasket product offers extensive customization services to meet your specific needs. Available in model numbers S14 and S8A, these gaskets are compatible with various heat exchanger types, including plate and shell and tube designs. We provide a wide selection of materials such as graphite, rubber, PTFE, or metal to ensure optimal performance and durability.

The gaskets come in colors like black, grey, or customized shades based on the chosen material. Installation options are versatile, featuring glue, hang-on, clip-on, snap-on, or Sonderlock types to suit your application requirements. Whether you need a gasketed plate heat exchanger rubber solution or a reliable PLATE HEAT EXCHANGER GASKET, our customized PHE gasket services are designed to deliver precision and quality.

Packing and Shipping:

Each Heat Exchanger Gasket is carefully packaged to ensure maximum protection during transit. The gaskets are individually wrapped in moisture-resistant material and placed in sturdy, corrugated cardboard boxes to prevent any damage or deformation.

For bulk orders, gaskets are stacked securely with protective separators and cushioned with foam inserts to avoid any movement inside the packaging. All packages are clearly labeled with product details, handling instructions, and shipping information.

Shipping is carried out using reliable carriers with tracking options available. We ensure timely dispatch and delivery, maintaining the integrity and quality of the Heat Exchanger Gaskets throughout the shipping process.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!