Product Description:

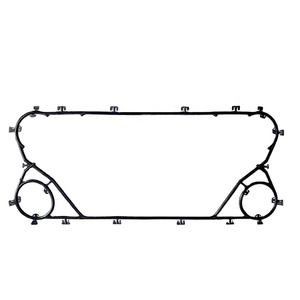

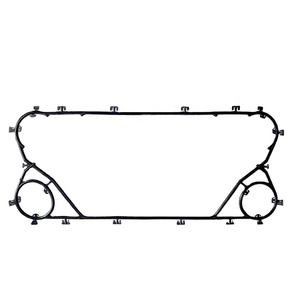

The Heat Exchanger Gasket is a vital component designed specifically for enhancing the performance and longevity of gasketed plate heat exchangers. Manufactured as a Solid Core Sealing Strip, this gasket provides exceptional sealing capabilities that ensure optimal operation of heat exchange systems. Its robust construction and high-quality materials make it an indispensable choice for industries requiring reliable and durable sealing solutions.

One of the standout features of this Heat Exchanger Gasket is its superior corrosion resistance. The gasketed plate heat exchanger rubber used in its composition is engineered to withstand aggressive chemical environments, thereby preventing degradation and maintaining sealing integrity over extended periods. This high corrosion resistance significantly reduces maintenance costs and downtime, making it an economical solution for various industrial applications.

Another critical attribute of this gasket is its impressive heat resistance. The gasket is capable of withstanding temperatures up to 170°C, making it suitable for heat exchangers operating in high-temperature environments. This heat resistance ensures that the gasket maintains its structural integrity and sealing performance even under thermal stress, providing reliable service in applications such as chemical processing, HVAC systems, and power generation.

The performance of this gasket in corrosion resistance is particularly noteworthy. It is designed to prevent leakage and withstand harsh conditions that would typically compromise lesser quality seals. This makes it an ideal choice for PHE Gasket applications where maintaining a secure, leak-free seal is crucial for the efficiency and safety of the heat exchanger system.

In terms of aesthetics and customization, the Heat Exchanger Gasket is available in multiple color options including black, grey, or as per the material specifications required by the customer. This flexibility allows for easy identification and compatibility with existing systems, while also catering to specific industry standards or preferences.

The gasketed plate heat exchanger rubber used in this product is formulated to provide a perfect balance between flexibility and strength. This ensures that the gasket can accommodate slight variations in plate alignment and surface irregularities, thereby enhancing the overall sealing effectiveness. The solid core sealing strip design further contributes to its durability and resistance to mechanical wear and tear.

Additionally, the gasket’s design and material selection are optimized to minimize thermal expansion and contraction effects, which can otherwise lead to seal failure. This careful engineering ensures a long service life and consistent performance, crucial for maintaining the operational efficiency of gasketed plate heat exchangers.

In summary, the Heat Exchanger Gasket is a high-performance sealing solution specifically crafted for gasketed plate heat exchanger rubber applications. Its solid core sealing strip type construction, high corrosion resistance, and heat resistance up to 170°C make it a reliable and durable choice for various industrial sectors. Available in black, grey, or customized colors, this gasket meets diverse operational and aesthetic requirements. Whether you need a PHE Gasket for routine maintenance or new installations, this product ensures excellent sealing performance, reducing leakage risks and enhancing the overall efficiency of your heat exchanger systems.

Applications:

The Heat Exchanger Gasket model S14 is designed for versatile application occasions and scenarios, making it an essential component in various heat exchange systems. Specifically tailored for Gasketed Plate heat exchanger rubber applications, this gasket ensures optimal sealing and durability under demanding conditions. Its compatibility with various heat exchanger types, including plate and shell and tube designs, highlights its adaptability across industrial and commercial settings.

One of the key application occasions for the S14 gasket is in the maintenance and repair of plate heat exchangers, where reliable sealing is crucial to prevent leaks and maintain system efficiency. The gasket's plate center size of 868*212mm fits a wide range of plate heat exchanger models, allowing for easy replacement and retrofitting in existing systems. This makes it highly suitable for industries such as HVAC, chemical processing, food and beverage production, and power generation, where heat exchangers play a vital role in thermal management.

The installation flexibility of this product further broadens its application scenarios. With multiple install types available including Glue, Hang-on, Clip-on, Snap-on, and Sonderlock methods, technicians can choose the most appropriate installation technique based on the specific requirements of the heat exchanger and operational conditions. This flexibility ensures a secure and lasting seal, reducing downtime and maintenance costs.

Moreover, the S14 gasket, along with the S8A model, is engineered to withstand heat resistant temperatures up to 170°C, making it ideal for high-temperature environments. This heat resistance is particularly important in processes involving hot fluids or steam, where gasket integrity directly impacts system safety and performance. The heat resistant properties of the gasketed plate heat exchanger rubber ensure longevity and reliability, even under fluctuating thermal stresses.

In summary, the PLATE HEAT EXCHANGER GASKET S14 serves a wide range of application occasions, from routine maintenance to system upgrades in various industrial sectors. Its compatibility with multiple heat exchanger types, robust heat resistance, and diverse installation options make it a preferred choice for ensuring efficient and leak-free heat transfer operations. Whether used in new installations or as a replacement part, this gasket provides dependable sealing performance that enhances the overall functionality of heat exchanger systems.

Customization:

Our S14 model PHE Gasket is designed to meet the specific requirements of your heat exchanger. We offer product customization services to ensure the gasket perfectly fits your equipment. The dimensions of the gasket are customizable according to the heat exchanger model, with a plate center size of 868*212mm, providing a transfer area of 1.13m² for optimal performance.

Manufactured to deliver excellent corrosion resistance, this gasketed plate heat exchanger rubber guarantees durability and reliability in demanding environments. Each PHE Gasket is carefully packaged in a standard export carton to ensure safe transport and delivery.

Trust our customization services to provide you with the ideal gasket solution tailored to your heat exchanger’s specifications, ensuring enhanced efficiency and long-lasting performance.

Packing and Shipping:

Each Heat Exchanger Gasket is carefully packaged to ensure maximum protection during transit. The gaskets are individually wrapped with protective materials to prevent any damage or deformation.

The packaged gaskets are then placed in sturdy, labeled boxes designed to withstand handling and shipping conditions. For bulk orders, the boxes are securely packed on pallets and shrink-wrapped to maintain stability.

We offer various shipping options tailored to meet your delivery requirements, including standard, expedited, and freight services. All shipments are tracked and insured to guarantee safe and timely delivery.

Upon receiving your order, please inspect the packaging for any signs of damage before accepting the shipment. In case of any issues, contact our customer service team promptly for assistance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!