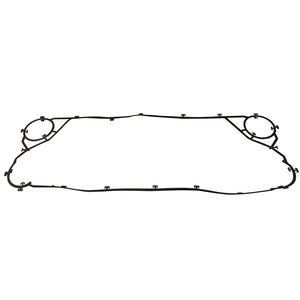

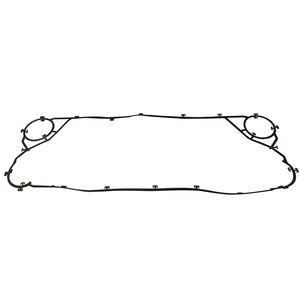

Product Description:

The Heat Exchanger Gasket is a vital component designed specifically for use in gasketed plate heat exchangers, ensuring optimal sealing performance and durability under various operating conditions. Manufactured from high-quality materials such as graphite, rubber, PTFE, or metal, this gasket offers exceptional corrosion resistance, making it suitable for a wide range of industrial applications where chemical exposure and temperature fluctuations are common. The versatility in material selection allows users to choose the most appropriate gasket type based on the medium being processed and the specific requirements of their heat exchanger system.

One of the standout features of this product is its superior corrosion resistance. The materials used in the construction of this PHE gasket are carefully chosen to withstand aggressive chemicals, high temperatures, and prolonged exposure to moisture, thereby significantly extending the lifespan of the heat exchanger. This high corrosion resistance ensures that the gasket maintains its sealing integrity over time, reducing the risk of leaks and minimizing maintenance needs. As a result, the heat exchanger operates more efficiently and reliably, contributing to overall system performance and cost savings.

The Heat Exchanger Gasket is fully customizable according to the dimensions of the specific heat exchanger model it is intended for. This customization capability ensures a perfect fit, which is essential for maintaining the tight seal required in gasketed plate heat exchangers. Whether you are replacing an existing gasket or outfitting a new heat exchanger, these gaskets can be tailored to match the exact measurements, contours, and specifications of your equipment. This level of precision helps to prevent common issues such as gasket displacement or uneven sealing, which can lead to operational inefficiencies or equipment damage.

Specifically designed for use as a gasketed plate heat exchanger rubber component or as a PLATE HEAT EXCHANGER GASKET, this product is compatible with a wide range of heat exchanger models. The rubber variants provide excellent flexibility and resilience, accommodating thermal expansion and mechanical stresses without compromising the seal. Additionally, PTFE gaskets offer outstanding chemical resistance and low friction, while graphite gaskets excel in high-temperature applications. Metal gaskets, on the other hand, provide enhanced strength and durability for heavy-duty industrial processes.

In terms of logistics and packaging, the Heat Exchanger Gasket is shipped in a standard export carton that ensures safe and secure transport worldwide. This packaging method protects the gasket from damage during transit and storage, preserving its quality until it reaches the end user. The efficient packing also facilitates easy handling and inventory management, making it convenient for distributors and customers alike.

Overall, the Heat Exchanger Gasket is an indispensable part for anyone utilizing gasketed plate heat exchangers, providing reliable sealing solutions that enhance the performance and longevity of the equipment. Its high corrosion resistance, customizable dimensions, and availability in multiple materials such as graphite, rubber, PTFE, and metal make it an excellent choice for various industrial sectors including chemical processing, HVAC, food and beverage, and pharmaceuticals. Whether you need a robust PHE gasket for demanding environments or a flexible gasketed plate heat exchanger rubber option, this product delivers consistent quality and dependable service.

Applications:

The S14 model Plate Heat Exchanger Gasket (PHE Gasket) is specifically designed to meet the demanding requirements of various industrial applications where reliable sealing and high performance are crucial. Made from premium materials such as graphite, rubber, PTFE, or metal, this gasket ensures excellent durability and adaptability to different operational environments. The gasket materials include NBR, EPDM, HNBR, HEPDM, Viton, FKM, and HTNBR, offering a wide range of options to suit specific chemical and temperature resistance needs. This versatility makes the S14 Plate Heat Exchanger Gasket an ideal choice for a broad spectrum of heat exchanger models, as its dimensions can be customized according to the specific heat exchanger in use.

One of the primary application occasions for the S14 Plate Heat Exchanger Gasket is in the chemical processing industry, where corrosive fluids and aggressive media are handled regularly. Thanks to its high corrosion resistance, the gasket provides a secure seal that prevents leaks and ensures the safe operation of the heat exchanger. It is also widely used in the food and beverage industry, where hygiene standards are stringent, and the gasket’s ability to withstand various cleaning agents and temperature fluctuations is invaluable.

The oil and gas sector is another key application scenario for the S14 PHE Gasket. Here, the gasket’s robustness and corrosion resistance contribute to maintaining efficiency and safety in heat exchangers exposed to harsh environments and aggressive substances. Additionally, the gasket is suitable for HVAC systems, power plants, and pharmaceutical manufacturing, where reliable thermal management and chemical resistance are essential.

With customizable dimensions tailored to each heat exchanger model, the S14 Plate Heat Exchanger Gasket ensures a perfect fit, minimizing downtime and maintenance costs. Its excellent performance under high pressure and temperature conditions makes it a dependable solution in both new installations and retrofit applications. Overall, the S14 Plate Heat Exchanger Gasket combines material versatility, corrosion resistance, and high sealing performance to meet the diverse needs of modern industrial heat exchange systems.

Customization:

Our Product Customization Services for the Heat Exchanger Gasket, model number S14, offer tailored solutions to meet your specific needs. The S14 gasket is suitable for various heat exchanger types, including plate and shell and tube designs, ensuring versatile compatibility.

With a transfer area of 1.13m², this gasket is designed to optimize performance in heat transfer applications. Available in black, grey, or customized colors based on the material used, the gasket can be adapted to match your equipment requirements.

Constructed with high corrosion resistance, the S14 gasket delivers reliable and long-lasting performance, making it ideal for demanding environments. This makes it an excellent choice for PHE gasket applications and gasketed plate heat exchanger rubber components.

Our customization services ensure that each PLATE HEAT EXCHANGER GASKET is manufactured to precise specifications, enhancing the efficiency and durability of your heat exchanger system.

Packing and Shipping:

Each Heat Exchanger Gasket is carefully packaged to ensure maximum protection during transportation and storage. The gaskets are individually wrapped in protective materials to prevent damage and contamination. They are then placed in sturdy, labeled boxes that provide cushioning and support.

For bulk orders, the gaskets are securely stacked and palletized to facilitate safe handling and efficient shipping. All packages are sealed and clearly marked with handling instructions and product information.

We use reliable shipping services to ensure timely delivery to your specified location. Tracking information is provided for all shipments to keep you informed throughout the delivery process.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!