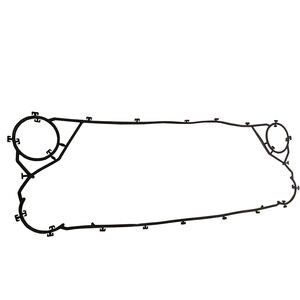

Product Description:

The Heat Exchanger Gasket, Model No: S8A, is a premium quality sealing solution designed specifically for plate heat exchangers. Engineered to meet the demanding requirements of industrial applications, this gasket ensures optimal performance and longevity in various heat exchange systems. One of the standout features of this product is its exceptional heat resistance, capable of withstanding temperatures up to 170°C. This makes it an ideal choice for environments where high thermal stability is critical, ensuring reliable sealing without degradation under intense heat conditions.

As a vital component in plate heat exchangers, the PHE Gasket plays a crucial role in maintaining the integrity of the heat exchanger by preventing leaks and ensuring efficient heat transfer between fluids. The S8A model is specifically crafted to offer superior corrosion resistance, which is essential in industries where aggressive chemicals and harsh fluids are common. Its high corrosion resistance protects the gasket from chemical wear and tear, thereby extending the service life of the entire plate heat exchanger system.

The Plate Heat Exchanger Gasket is manufactured using advanced materials that combine durability with flexibility. This balance allows the gasket to form a tight seal even under fluctuating pressure and temperature conditions, reducing the risk of operational failures. The gasket’s performance in resisting corrosion also means it maintains its structural integrity over time, minimizing maintenance requirements and downtime for repairs or replacements.

In addition to its technical attributes, the Heat Exchanger Gasket S8A comes with a comprehensive 1-year warranty. This warranty underlines the manufacturer’s confidence in the product’s quality and reliability. Customers can trust that the gasket will perform as expected throughout its warranty period, providing peace of mind and ensuring cost-effectiveness in heat exchanger maintenance.

The PLATE HEAT EXCHANGER GASKET is designed for ease of installation and compatibility with a wide range of plate heat exchanger models. Its precise dimensions and material composition enable a perfect fit, which is critical for maintaining the efficiency and safety of the heat exchange process. Whether used in HVAC systems, chemical processing plants, or food and beverage production, this gasket delivers consistent sealing performance.

Choosing the right PHE Gasket is crucial for the efficiency and durability of plate heat exchangers. The S8A model stands out due to its heat resistance up to 170°C and high corrosion resistance, making it suitable for challenging industrial environments. Its robust design and reliable sealing capability help optimize the heat transfer process, reduce energy consumption, and prevent costly leaks and equipment damage.

Overall, the Heat Exchanger Gasket Model No: S8A is a reliable, high-performance sealing solution that meets the stringent demands of modern plate heat exchangers. Its combination of heat resistance, corrosion resistance, and warranty support makes it an excellent investment for businesses seeking to enhance the operational efficiency and longevity of their heat exchange systems. By incorporating this PLATE HEAT EXCHANGER GASKET into your equipment, you ensure superior sealing performance, reduced maintenance costs, and improved system reliability.

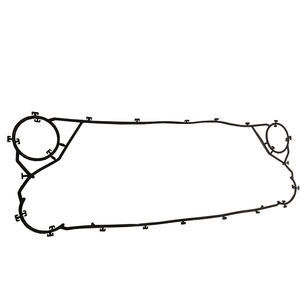

Applications:

The PLATE HEAT EXCHANGER GASKET, model number S14, is specifically designed to meet the demanding needs of various industrial applications. With a plate center size of 868*212mm and a transfer area of 1.13m², this gasket is ideal for use in gasketed plate heat exchanger systems requiring reliable sealing and efficient thermal transfer. Its solid core sealing strip construction ensures durability and enhanced performance in sealing operations, making it a vital component in heat exchanger maintenance and assembly.

This gasket excels in scenarios where corrosion resistance is critical. The high-performance corrosion resistance feature of the S14 gasketed plate heat exchanger rubber makes it highly suitable for chemical processing plants, food and beverage industries, pharmaceutical manufacturing, and HVAC systems. In these environments, the gasket withstands aggressive fluids and varying temperatures, ensuring leak-free operation and minimizing downtime.

Additionally, the S14 heat exchanger gasket is perfectly suited for applications in power plants and marine equipment, where harsh environmental conditions demand robust sealing solutions. Its compatibility with a wide range of media, combined with its solid core sealing strip design, provides superior sealing integrity and longevity. The gasket’s ability to maintain a tight seal under fluctuating pressures and temperatures enables optimal heat transfer efficiency and reliable system performance.

For transport and storage, the S14 gasket is packaged in a standard export carton, ensuring safe delivery and ease of handling. This packaging approach protects the gasket from damage and contamination prior to installation, maintaining its quality and readiness for immediate use. Maintenance teams and system integrators appreciate this attention to packaging, as it simplifies logistics and inventory management.

In summary, the PLATE HEAT EXCHANGER GASKET S14 is an essential component for industries utilizing gasketed plate heat exchanger rubber. Its precise dimensions, corrosion resistance, and solid core sealing strip type make it a dependable choice for applications spanning chemical processing, food production, energy generation, and HVAC systems. Whether for routine maintenance or new installations, this gasket ensures efficient, leak-proof operation, maximizing the lifespan and performance of gasketed plate heat exchanger units.

Customization:

Our Heat Exchanger Gasket model S14 offers versatile product customization services to meet your specific needs. Designed as a solid core sealing strip, this gasket is suitable for various heat exchanger types, including plate and shell and tube configurations. Whether you require a PLATE HEAT EXCHANGER GASKET, a PHE Gasket, or a gasketed plate heat exchanger rubber, model S14 provides reliable sealing performance.

The S14 gasket supports multiple installation types such as glue, hang-on, clip-on, snap-on, and Sonderlock, ensuring compatibility with your existing systems. Each gasket is carefully packaged in a standard export carton to guarantee safe transport and delivery. Additionally, we back our product with a 1-year warranty, reflecting our commitment to quality and customer satisfaction.

Customize your heat exchanger sealing solutions with the S14 model for enhanced durability and optimal sealing efficiency across various heat exchanger applications.

Packing and Shipping:

The Heat Exchanger Gasket is carefully packaged to ensure protection during transit and storage. Each gasket is individually wrapped in a protective film to prevent damage and contamination. The wrapped gaskets are then placed in sturdy, corrugated cardboard boxes that provide cushioning and support. For bulk orders, multiple boxes are securely packed into wooden crates or pallets, depending on shipment size and destination.

All packages are clearly labeled with product information, handling instructions, and shipping details to ensure safe and efficient delivery. We use reliable shipping carriers and provide tracking information to monitor the shipment status. Our packaging and shipping processes comply with international standards to guarantee that the Heat Exchanger Gasket arrives in perfect condition and ready for use.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!